"There are many options when choosing an insulation system for your next project. "

October 2, 2020

by Star Building Systems

In my last blog post, I shared my top 3 tips for insulating metal buildings, which included knowing code requirements that impact your projects, understanding the insulation options available, and ordering the metal building with the insulation system in mind. I received many questions about insulation systems; everything from when to opt for a banded liner system versus a long tab banded system, which continuous insulation systems satisfy code requirements, and what type of systems are best for specific applications. So, let’s take a deeper look at the latest trends in insulating metal buildings and the differences between each insulation system available in today’s market.

Metal Building Insulation Categories

Before we dive into specific insulation systems, it’s important to understand the basic categories that each system is classified under. The primary categories referenced throughout energy code literature include:

Types of Fiberglass Systems

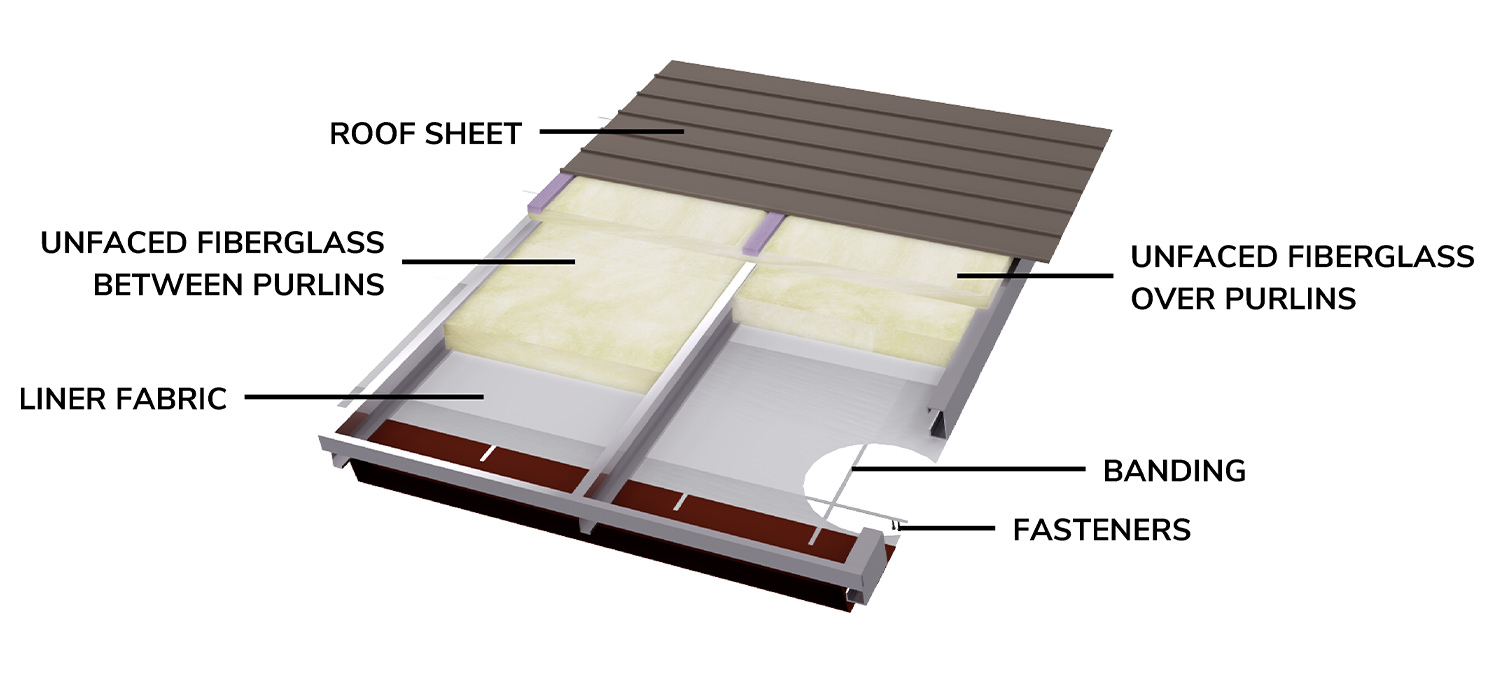

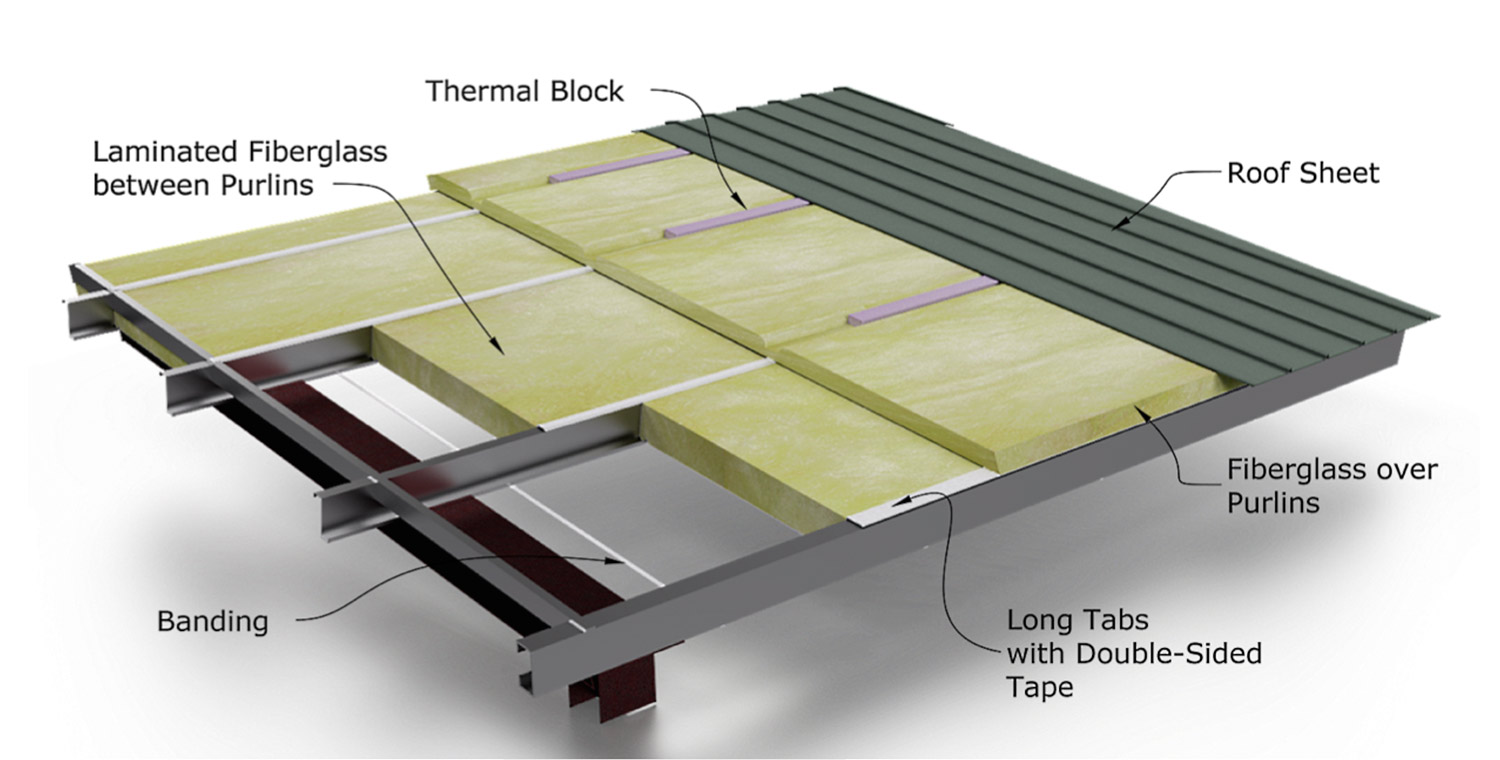

The fiberglass insulation systems most often used to meet code include Banded Liner Systems and Long Tab Banded Systems. Both systems provide High-R insulation to meet the latest codes, and both include two layers of fiberglass and banding. However, there are several key differences between the two, including:

Types of Continuous Insulation Systems

Continuous insulation systems (CI) have become more prevalent in metal buildings over the last few years, primarily due to two key characteristics: CI provides a high R-value per inch, and most systems are easy to install. Systems typically consist of a rigid polyisocyanurate or polyethelene foam core and the majority can be used in both the roof and walls. There are various continuous insulation systems available to meet code, and building manufacturers have components for this application. Contractors also must understand board insulation applications do require specific fire testing to be used in exposed applications. Many off-the-shelf board insulations do not meet the requirement. Additionally, insulated metal panels have gained market share in recent years, with a specific focus on wall applications.

Insulated Metal Panels

Insulated metal panels (IMPs) are made up of factory-controlled foam insulation sandwiched between a finished metal exterior and an interior face. IMPs deliver a high R-value per inch and can be used to meet energy codes. A specific focus on IMPs for wall applications has emerged over the last several years.

Closing Remarks

As you can see, there are many options when choosing an insulation system for your next project. Often it boils down to budget, building requirements and contractor preference.

Bill Beals, District Manager of Therm-All, is a 32-year veteran of the metal building industry and a contributing member of several committees, including the Metal Building Manufacturers Association (MBMA) Energy Committee and NIA’s Metal Building Insulation Laminators Committee (chairperson). Bill also belongs to the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) and International Code Council (ICC), and is often invited to share his extensive energy code knowledge through presentations at industry conferences. Bill has contributed to many articles and reference guides, and authors a bi-monthly commercial energy codes blog called “The Code Man”. Beals can be reached at [email protected].

Become part of the powerful Star network. We invest in builders who understand the value of results and provide support that develops strong relationships between you and the entire Star team.

Your building is the cornerstone of the community where people live, work and play. Find a local Star Authorized Builder and let us help you bring your vision to life.