April 18, 2016

by Star Building Systems

Picture yourself climbing onto the roof of your metal building to complete an add-on, take care of a vent, or just take a look around. Everything looks great. The panels are still glossy after only a few years of wear and tear, but then something nasty catches your eye—something rusty. An orange-brown, crusty fastener sends you reeling, and as you take a closer look at your roof situation, you discover the problem goes way beyond one screw. Every fastener on the roof is ugly, and that’s bad, or is it?

With fasteners, sometimes, you shouldn’t let your eyes fool you. The rust you see may not be corrosion of the body of the fastener. It’s probably only occurring on the head, and that doesn’t affect the fastener’s performance. Also, remember that fasteners are the first components of any new building to show the consequences of Mother Nature’s influence. Of all materials, they’ll rust first, so again—don’t panic.

The rust you “see” on the fastener is likely caused by elements that have landed on the head—elements delivered through condensation, rain, or a variety of exposures. Those elements have stained only the head or filings from installation, and basically, the only consequence of that staining is the changing color of your fastener’s head. The overall function is still very much protected.

But to many builders, that dull orange = roof cancer. It makes them feel like they have only a handful of days to fix the entire roof before a storm hits and blows everything away—including their career. But luckily—none of that is true. The rust stain is only on the surface.

To ensure this is true, do a scratch test. Use an eraser or a scraper to remove the rust. If the metal below looks healthy, you’re good. If the metal below looks pockmarked with deterioration, then you will definitely need to switch out the fastener, because it can dissolve further and ultimately fail.

Keep in mind; nowadays the rusting of the body of fasteners—and complete failure—is rare, because they’re zinc-plated and coated with a copolymer synthetic that does a great job of protecting the screw. Forty or fifty years ago, this wasn’t the case. Back then, they used cadmium-plated and enamel-painted fasteners. Cadmium has since been outlawed, and copolymer synthetic coating is the standard , so you simply don’t see the rust problem with the newer products.

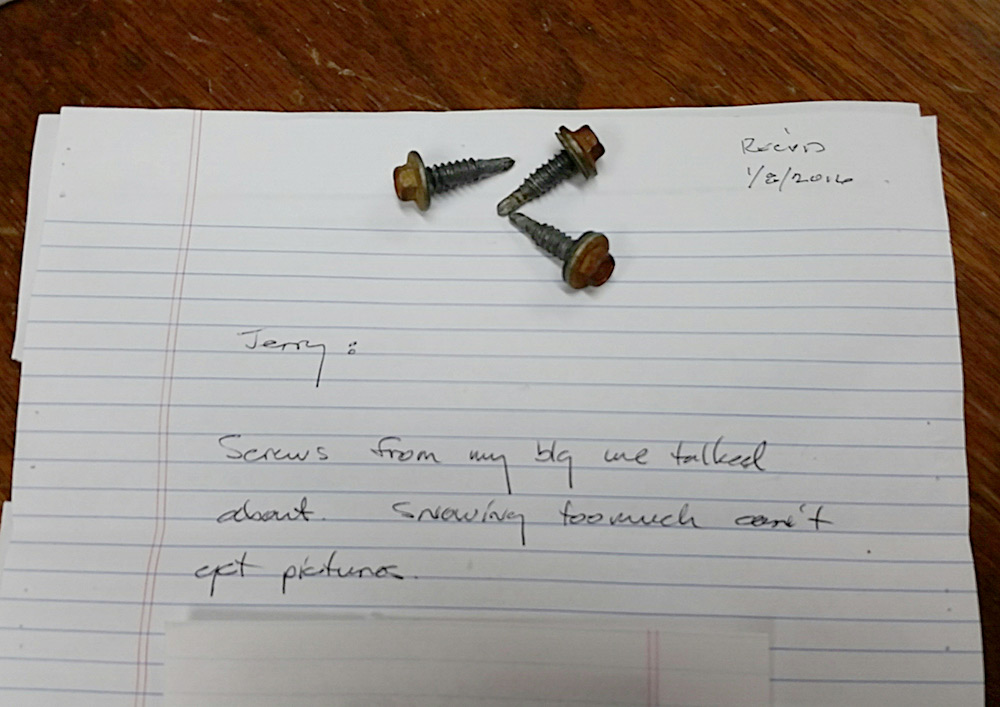

The photo above shows an actual letter sent to us from a Star builder who had a rusty fastener problem. When he first saw the rust, he called us. We talked him through the diagnosis, but to confirm he was looking at rust staining and not a corroded fastener, he mailed the fasteners to us. That way we could see exactly what was happening.

The fasteners you see in the photo are a basic, or entry-level, fastener. At Star, this is one of the fasteners we offer our builders, because they’re a great and affordable option. They cover light-commercial duty and are reliable as well as durable. Mind you, these are NOT high-end fasteners, and they are also NOT low-end fasteners. They are mid-range. The choice is completely up to you on type of fasteners you order.

We do not recommend low-end fasteners for use on extended product warranties or buildings with exposure to harsh environmental conditions.

As for long-life fasteners, if you passionately hate rust, then they’re right up your alley. High-end fasteners are slightly more expensive, because they are the crown jewels of the fastener world. When you put those on your roof, they will never rust. The heads are made out of materials that never can—stainless steel or aluminum die cast zinc. There is not one ounce of carbon steel in the exposed part of the head, and that’s why they stay nice over many years. They’re sexy and super-robust, but you’ll pay a slight upcharge for those traits.

So the choice is up to you! You can save a little money with the mid-range, respectable fasteners, which is what you see in the photo; and note that the bodies of the fasteners are just fine. The rusting was confined to the heads. With this builder’s fasteners, there was no need for him to remove and replace them based on service alone. But if he simply wanted a nicer appearance, than it was time for a swap. Rust stains were what this builder saw, and they were not a reason for panic. If a little rust on your fastener heads is an issue for you or your customer, remember that a fastener upgrade in SBS is as easy as the push of a button. It’s your choice to decide which options and price will work best for you and your customer.

Regarding you and your buildings’ fasteners, take note: Before you get overly nervous about them being rusted, just do the scratch test, and you’ll know where you stand.

Become part of the powerful Star network. We invest in builders who understand the value of results and provide support that develops strong relationships between you and the entire Star team.

Your building is the cornerstone of the community where people live, work and play. Find a local Star Authorized Builder and let us help you bring your vision to life.